Vertically Integrated Manufacturing ofHeavy Industrial Equipment

BETA SA operates a vertically integrated facility with advanced machining, welding, and assembly capabilities for pressure equipment up to 300 tons.

Our full in-house production chain ensures precision fabrication of ASME-certified and PED-certified pressure vessels, columns, and reactors for Oil & Gas, Petrochemical, Chemical, and Power Generation industries.

BETA S.A. Pressure Equipment Manufacturer

Facts & Figures

Founded in Buzău, Romania, BETA SA has more than a century of experience in custom fabrication of pressure equipment and process systems.

Fully integrated plant delivering over 3,500 tons of heavy-duty industrial equipment per year – including ASME certified and PED certified pressure vessels, reactors, fired heaters and skid-mounted units.

Our facility spans over 165,000 sqm (65,000+ sqm indoor) dedicated to welding, machining, hydrotesting, sandblasting, and large-scale assembly.

Skilled workforce with certified welders, engineers, and technicians trained for international quality standards and complex industrial projects.

Our Productsin numbers

Manufacturing Facilities

CNC Plasma & Laser Metal Cutting Hall

High-temperature plasma technology for fast and precise cutting of steel plates, ideal for heavy-duty industrial fabrication. We operate fully dedicated production halls for stainless steel, ensuring contamination-free processes across all stages: raw material storage, CNC cutting, cold forming, precision welding, clean assembling, and stainless shot-blasting. This segregation guarantees top-quality, corrosion-resistant stainless steel fabrication.

Versatile CNC laser systems with automated focus control for clean cuts through carbon and stainless steel up to 35 mm thickness. Ideal for pressure vessel and structural applications.

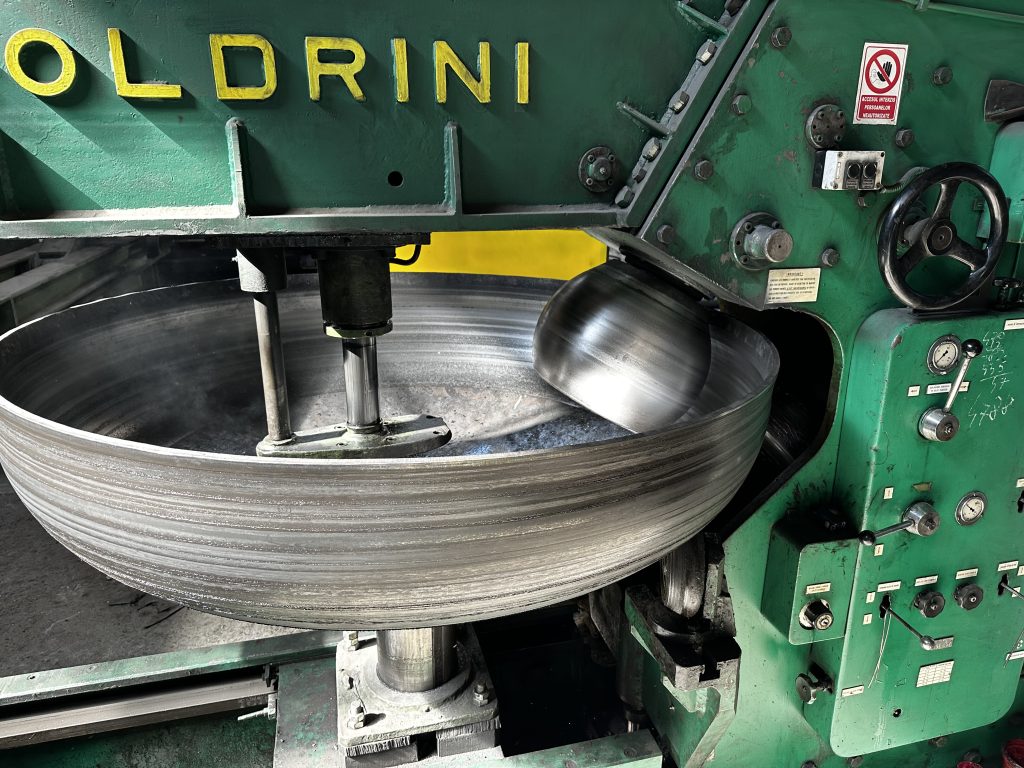

Mechanical Processing Hall

Our machining hall features advanced CNC technology (3–5 axes) for precision turning, milling, drilling, grinding, cutting, welding, and custom mechanical processing.

We ensure quality at every step using skilled inspectors. Our expertise in design and integration enables complex part and assembly manufacturing.

Our New Production Hall

Our new production hall features 50-ton overhead cranes (100-ton with twin bridge system) for safe assembly of large pressure vessels and heavy equipment.

Our automatic arc welding systems ensure consistent weld quality, enhanced productivity, and cost-efficiency for industrial manufacturing applications.

Auxiliary Halls & Facilities

ASME-compliant pressure testing is performed post-fabrication, including welding, NDE, radiography, and stress relieving for product integrity verification.

Shot-blasting and Sand-blasting facilities are preparing both standard and heavy-duty metal surfaces for painting or further processing, improving adhesion and removing surface contaminants. We operate fully dedicated production halls for stainless steel, ensuring contamination-free processes across all stages: raw material storage, CNC cutting, cold forming, precision welding, clean assembling, and stainless shot-blasting. This segregation guarantees top-quality, corrosion-resistant stainless steel fabrication.

The painting hall enables internal and external protective coating applications, aligned with project-specific vessel requirements and corrosion resistance standards.

Equipment

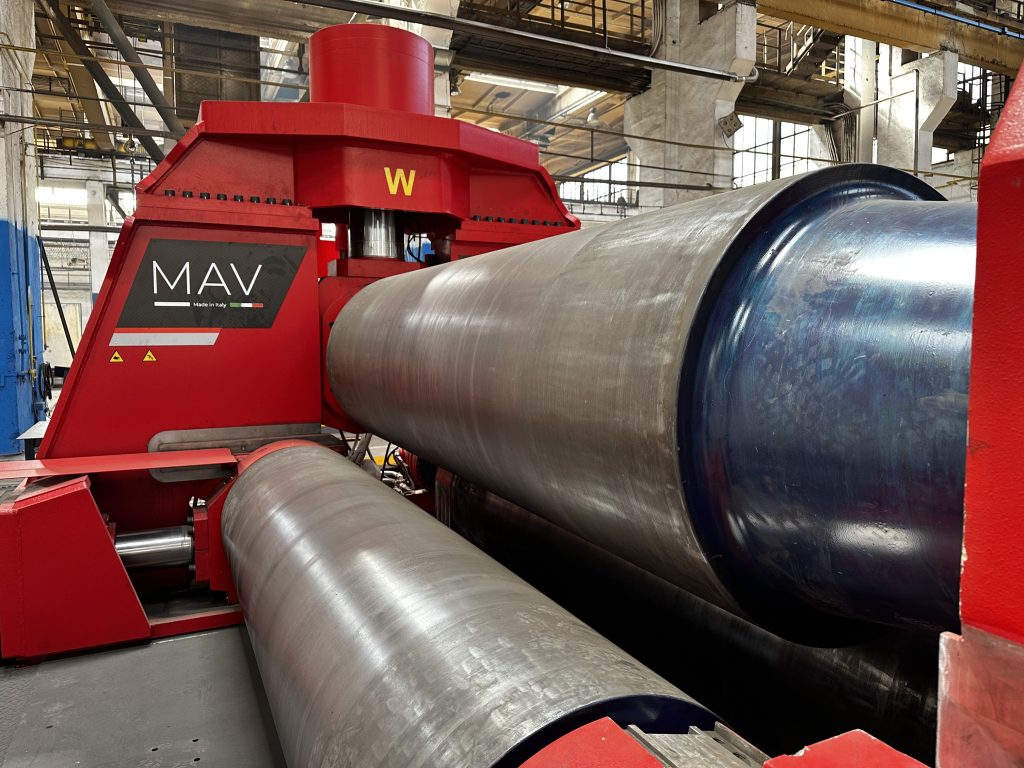

Advanced Metal Forming Equipment & Plate Rolling Capabilities

Rolls carbon steel plates up to 200 mm thick and 3050 mm wide, depending on yield strength – ideal for high-pressure shells and thick-walled vessels.

- Plasma & oxy-gas cutting installations - CNC automatic cutting - Guillotines and band saws - Manual & semiautomatic welding prep systems - Dish-end presses for head forming

Heat treatment equipment

Our metal heat treatment processes enhance mechanical properties by refining the metal’s microstructure. Through controlled thermal cycles, we improve hardness, strength, and structural integrity for superior industrial performance.

Our gas ovens work under 1100 C max. temperature with the following specifications:

Lenght - 15.5 m

Width - 4.4 m

Height - 4.5 m

When it is not possible to use the heat treatment oven, we can offer local heat treatments with electrical resistance for all types of joints and dimensions.

Up to date equipment and machine tools

Bevel length performance: 1,700 mm - 12,000 mm. Normal and vertical lathes. Different operating parameters ( vertical lathe Ø 4300 CNC)

Milling machines Forging machines Presses Bohnwerk machines Plasma Cutting Machines CNC Machines

2D3D design

Engineering & Design

Advance Workflow & Industrial Project Coordination

Our highly skilled engineers ensure seamless project coordination using advanced engineering software for industrial fabrication.

Minimize Downtime and Maximize Efficiency

We provide full-cycle services – from engineering design to fabrication, testing, packaging, and global delivery – ensuring efficiency and reliability at every stage.

ACCURATE measurements

Laboratory Testing

Safety, Quality & Certified Testing Procedures

All testing operations are performed in-house by certified inspectors in compliance with EN, ASME, and PED standards, ensuring product integrity and traceability.

NDE | Non-destructive Testing

– Radiographic Testing (RT / Rx) – weld seam verification

– Ultrasonic Testing (UT) – thickness & defect detection

– Phased Array Ultrasonic Testing (PAUT) – advanced flaw mapping

– Magnetic Particle Testing (MT) – surface/subsurface crack detection

– Liquid Penetrant Testing (LPT) – fine surface crack inspection

Destructive Testing (DT) Methods

– Tensile & impact mechanical tests

– Metallographic analysis

– Spectrometric chemical analysis

– Positive Material Identification (PMI)

ADVANCED welding capabilities

Welding Technologies

Certified Welding Processes for Pressure Vessel Manufacturing

We apply advanced welding procedures tailored to each pressure vessel’s service conditions – based on pressure, medium, and design code (ASME, EN). All welders are certified according to ISO 9606 and ASME IX.

We employ multiple welding techniques for carbon and stainless steel pressure vessels, including:

– SMAW (Shielded Metal Arc Welding) – versatile, site-friendly for repair welds

– FCAW (Flux-Core Arc Welding) – for high-deposition structural welds

– GMAW (Gas Metal Arc Welding / MIG) – productivity-focused for long welds

– GTAW (TIG) – precise welding for stainless steel and thin-wall pressure parts

– SAW (Submerged Arc Welding) – deep penetration welds for thick shells and heads

CERTIFICATES

BETA holds multiple internationally recognized certifications, ensuring the quality and compliance of our manufacturing services, built on decades of industrial experience.

Got questions? Contact our friendly team.

39 Santierului Street, 120226 Buzau, Romania

Ph: +40-238-725 500

Fax: +40-238-710 779

Sent us an email at

beta@betabuzau.com

Contract us at: ilie.petre@betabuzau.com